No. 63 of Lousangmiao Village Songlindian Town,

Zhuozhou, Hebei, China.

wafer backside grinding and sawing equipment

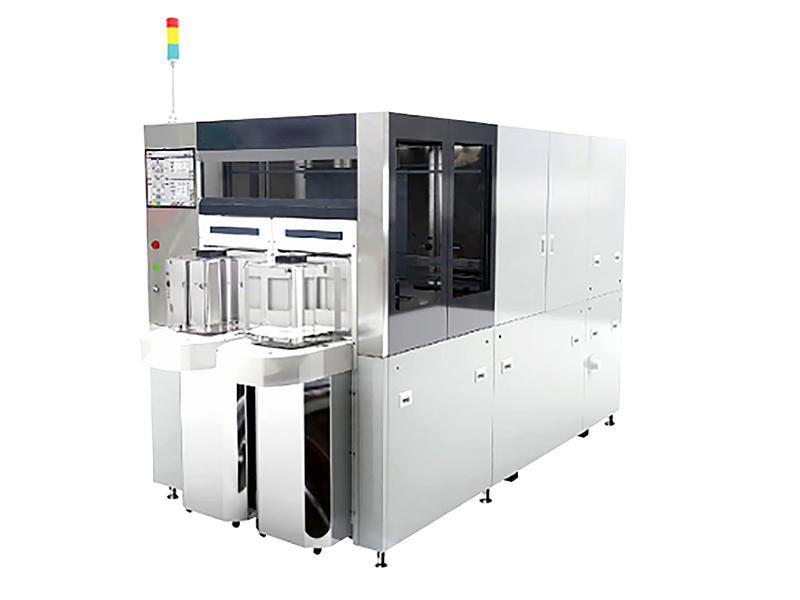

12-inch Backside Grinding: W-251 Automatic Grinding Machine

Equipment Introduction

The W-251 Automatic Grinding Machine is used in semiconductor manufacturing to reduce the thickness of wafers by removing partial material on the backside of wafers, which can increase the mechanical strength of wafers, improve thermal performance, and facilitate subsequent process steps such as packaging and testing.

Equipment Features:

Support axial feed (In-Feed) grinding principle. The equipment is equipped with online measuring instrument unit, which can precisely control thinning thickness. Equipped with 12-inch ultra -precision air spindle with independent property rights. Its rough grinding and fine grinding trajectory coincidence technology can effectively improve the stability of thinning processing, ensure the processing accuracy. With extended function, the equipment can form an online system with a single-axis polisher and a multifunctional wafer protective film processing equipment to realize the integration of wafer thinning to stress relief technology.

Spindle number: 2

Spindle speed: 1000-4000rpm

Thinning accuracy (thickness deviation within chip): ≤3μm

Thinning accuracy (thickness deviation between chips): ≤±3μm

Roughness average Ra:≤0.2μm

Equipment size: L*W*H=1445*3330*1895mm

Equipment weight: 5000Kg

-

For information of more similar products, contact us to get.