No. 63 of Lousangmiao Village Songlindian Town,

Zhuozhou, Hebei, China.

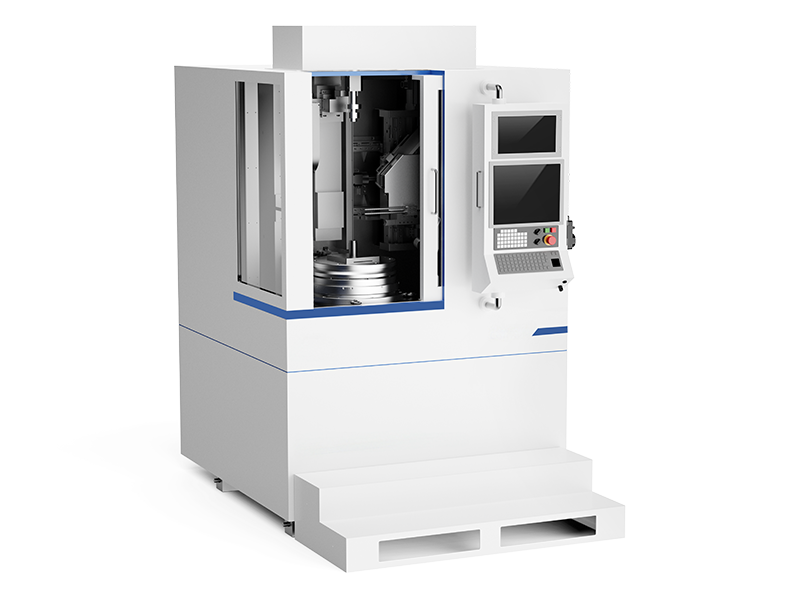

ultra-precision CNC optical centering lathe

For automatic detection and processing correction of deviations of the optical axis of the lens from the geometric axis of the mirror base, in order to improve the mounting accuracy and imaging quality of optical lens assemblies.

LCK-400V Ultra-precision CNC Optical Centering Lathe

For automatic detection and processing correction of deviations of the optical axis of the lens from the geometric axis of the mirror base, in order to improve the mounting accuracy and imaging quality of optical lens assemblies.

With one-time clamping, it can realize automatic centering of optical axis and simultaneous processing of upper and lower endface and outer circle, the height error from the top of the lens to the endface of the mirror base is <2μm, the centering accuracy of the optical axis of the lens and the axis of the mirror base is <3μm, the angular deviation between the optical axis of the lens and the axis of the mirror base is <3″, and the circularity and cylindricity of the mirror base are <2μm, and the lens with arbitrary radius of curvature can be measured by matching with the corresponding coupler lenses.

Materials that can be processed for mirror holders include stainless steel, titanium alloy, aluminum alloy, copper alloy, and so on.

Main Features

- Ultra-precision hydrostatic rotary table

- Natural granite bed and column.

- Linear axis adopts high-precision linear motion vice, high-precision scale

- Dual optical path optical eccentricity measuring system

- Automatic centering of optical axis, tilt and translation can be adjusted individually.

- On-line measuring system

- CK3M programmable controller

- Compressed air treatment system

-

For information of more similar products, contact us to get.